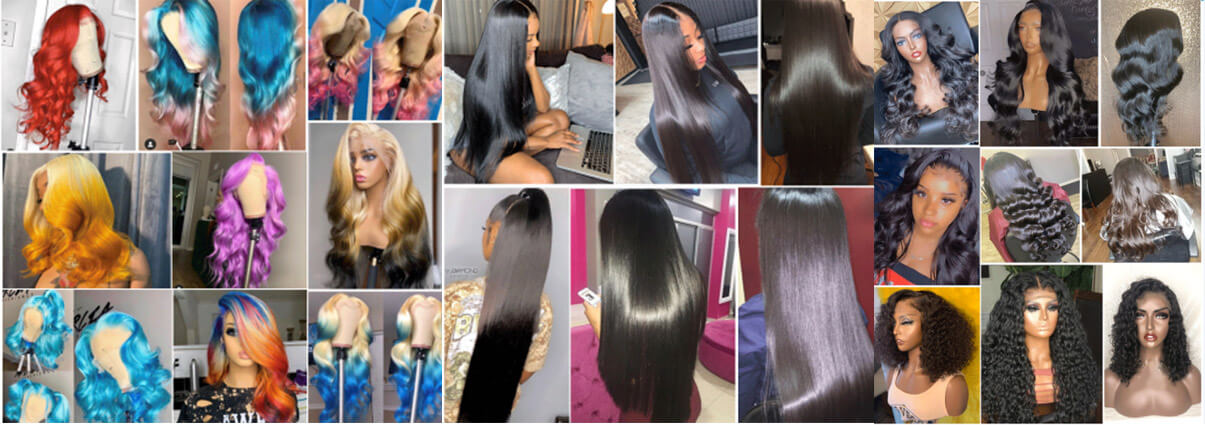

KBL hair factory, focus on produce and wholesale 100% raw virgin hair

About Us

KBL hair factory was founded in 2007 with 14 years experience in this hair line. We are a professional manufacturer and exporter specialized in research, production, wholesales and service.

Quality first! In quality management, We set up a impeccable quality control system to promise all items have to pass strict inspection before shipment. The factory covers an area of 3000 square meters with a high efficiency production team with 300 people to offer fresh and full stock available with the best factory price for wholesale. There are about 10,000 pieces hair waiting for ship out everyday.

In addition to an efficient production team, KBL has a professional sales team with over 200 salesmen to offer sincere customer service. We also attend lots of beauty shows in different countries to set up business relationship with more distributors. What's more, we also offer special service for customers such as OEM to meet different customers needs.

KBL cooperates with four express logistics companies: FEDEX, DHL, UPS and TNT to ship out packages everyday. We also offer drop shipping to help you manage your daily orders easily.

Why Choose KBL As A Reliable Hair Vendor?

Factory & Warehouse

Product Process

1

2

3

4

5

6

7

8

1.Raw material patting

KBL has a specialized raw materials purchasing department,we have a strict raw material purchasing standard on inspecting,sorting,classifing and picking out the unqualified raw materials fundamentally to ensure the hair quality.And to avoid hair shedding and tangling,we will comb and pat to make each hair in the same line.

2.Hair bulk weighing

KBL weighing department weighs each pieces hair bulk before sending to the production department to make sure the weight for per bundle is qualified. Meanwhile the unqualified bundles will be screened out and used for making other accessories products.

3.Wefts machine-making

KBL production department firstly use three locomotives to make Triple hair wefts and get triple guaranteed.That's why we have strong wefts.What's more,natural ingredients glue is applied in hair wefts to avoid shedding.

4.Wefts combining

Secondly we will use another two locomotives to combine those triple wefted hair with two pieces to offer another reliable and double guaranteed for the clients.

5.Quality controlling

KBL sets up a standard to control the hair quality.They check each parts of the finished products and then sort out the qualified one.Each bundle will be accurately measured and partly trimed the bottom to make sure the best hair received by the clients.

6.Deeply washing & Caring

KBL sets up a three-washing and caring standards:

1.Hand-washing with the warm water to wipe off the dirt and odor

2.Using weak acid shampoo together with natural hair conditioner to deep cleanse the hair

3.Adding rich human hair nutrition oil to fifty degree pure water can protect the internal protein,it will look more energetic after absorbed more nutrition.(Ps:We use the filtered pure water during the entire process)

7.Weaving head combing

8.Air drying & sealing

The hair will be dry when meet the hot wind or other heating methods,Here KBL promises that we only expose hair to the nutural air for drying and it ups to 24 hours,then seal them up in time in order to offer the freshest hair products to every clients."

Customer Review

Request a Quote